In today’s fast-paced industrial landscape, custom sheet metal fabrication enclosures play a critical role in protecting electronic systems, mechanical assemblies, and sensitive components across various sectors. These enclosures are engineered to offer precision, durability, and adaptability—all essential for modern equipment.

Linkwork Precision Machinery, a trusted name in precision part manufacturing, specializes in CNC machining, CNC turning, CNC milling, and sheet metal fabrication. With a proven track record in delivering customized solutions for industries such as electronics, automation, aerospace, automotive, medical, and more, Linkwork is at the forefront of high-performance enclosure fabrication.

Here are the top six advantages of using custom sheet metal fabrication enclosures for your industrial applications:

1. Tailored to Your Exact Specifications

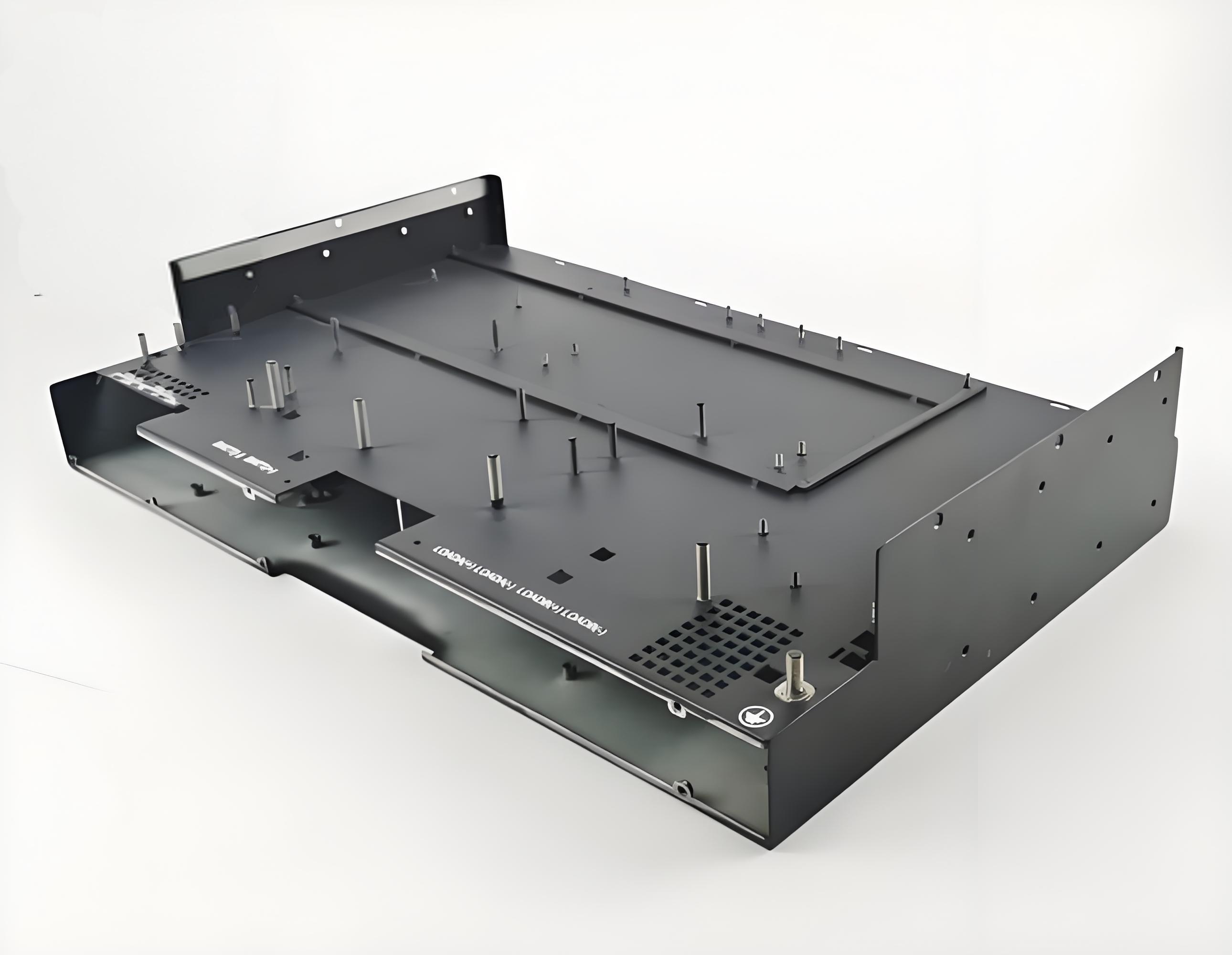

One of the most significant benefits of custom enclosures is design flexibility. Unlike off-the-shelf enclosures, custom-made solutions can be engineered to meet precise dimensional, structural, and functional requirements. Whether it’s unique port configurations, mounting options, or ventilation needs, Linkwork Precision Machinery can deliver tailor-made solutions that perfectly fit your equipment.

2. Superior Durability and Protection

Custom sheet metal enclosures are typically made from high-quality materials such as aluminum, stainless steel, or galvanized steel. These metals provide exceptional strength and resistance to corrosion, impact, and extreme environmental conditions—making them ideal for use in harsh industrial environments.

Linkwork’s advanced fabrication capabilities ensure tight tolerances and robust construction, safeguarding your components from dust, moisture, heat, and mechanical damage.

3. Enhanced Aesthetics and Branding

A custom enclosure isn’t just functional—it can also enhance the appearance of your equipment. Custom surface finishes, laser engravings, color coatings, and branding elements can be incorporated into the design to align with your company’s identity and product aesthetics. This is especially valuable in consumer-facing products and high-end machinery.

4. Improved Heat Dissipation and Airflow Management

Many electronic devices generate heat during operation, and improper ventilation can lead to system failures. Custom sheet metal enclosures allow for the integration of heat sinks, fan mounts, louvers, or perforations exactly where needed to promote efficient thermal management.

With Linkwork’s experience in serving sectors like electronics and automation, every enclosure can be optimized for performance and longevity.

5. Cost-Effective for Complex Requirements

While custom solutions may have higher initial tooling costs, they often lead to savings in the long run—especially for complex projects that would require modifications to standard enclosures. Custom enclosures reduce assembly time, minimize part incompatibility, and eliminate the need for post-production alterations.

Linkwork’s vertically integrated manufacturing approach ensures streamlined production processes and competitive pricing for small and large batch orders alike.

6. Cross-Industry Applications and Compliance

Custom sheet metal enclosures are widely used in industries ranging from aerospace and medical to agriculture and renewable energy. Customization enables easier compliance with industry standards, such as IP ratings, EMC shielding, and UL certifications, which are essential in regulated industries.

Linkwork has successfully provided compliant enclosure solutions across multiple sectors, demonstrating the versatility and reliability of its manufacturing systems.

Conclusion

If you're looking for a high-quality, long-lasting, and precisely engineered enclosure solution, custom sheet metal fabrication is the way to go. Companies like Linkwork Precision Machinery offer not just manufacturing capabilities, but engineering expertise to bring your vision to life.

Whether you need enclosures for automation equipment, medical instruments, or aerospace applications, investing in a custom solution means investing in the performance, reliability, and future-readiness of your product.

Ready to get started? Contact Linkwork Precision Machinery today to explore custom fabrication solutions tailored to your needs.

www.szlinkwork.com

Shenzhen Linkwork Precision Machinery Co., Ltd.