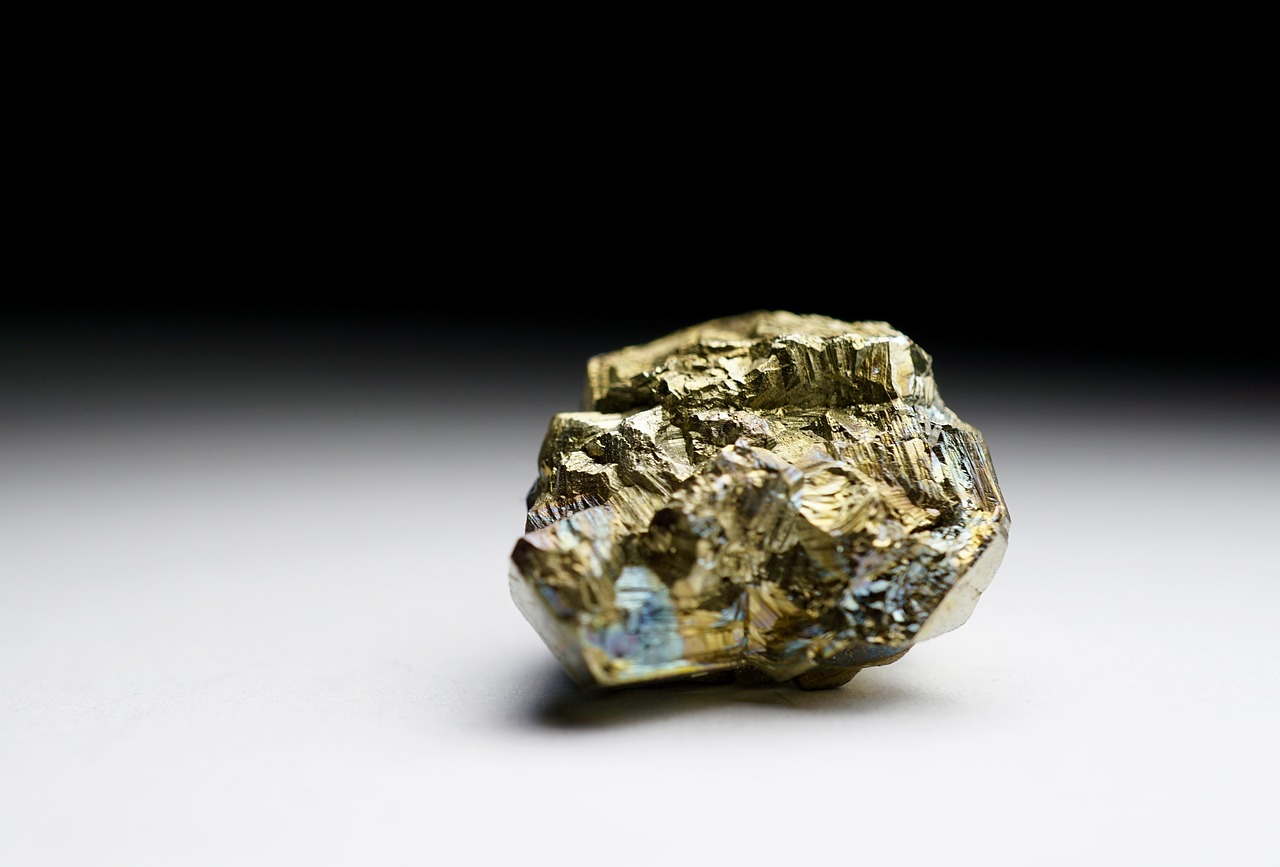

Mining and processing minerals play a crucial role in various industries, from construction and manufacturing to technology and energy production. Understanding the intricate processes involved in extracting and refining minerals is essential for optimizing efficiency, minimizing environmental impact, and ensuring sustainable resource management. In this comprehensive guide, we delve into the world of mineral mining and processing, exploring the techniques, challenges, and advancements that shape this vital industry.

- Exploration and Site Selection:

Before mining can commence, extensive exploration and site selection processes are undertaken. Geologists employ various methods, including remote sensing, geochemical analysis, and drilling, to identify potential mineral deposits. Factors such as deposit size, grade, accessibility, and environmental considerations influence site selection. - Extraction Techniques:

Once a viable deposit is identified, the extraction process begins. Different minerals require different extraction techniques. Common methods include open-pit mining, underground mining, placer mining, and mountaintop removal. Each technique has its advantages and challenges, such as safety concerns, cost-effectiveness, and environmental impact. - Crushing and Grinding:

After extraction, the mineral-bearing ore undergoes crushing and grinding to reduce its size for further processing. Crushing involves breaking the ore into smaller pieces, while grinding involves reducing the particle size to facilitate mineral separation. Advanced technologies, such as autogenous grinding and high-pressure grinding rolls, have revolutionized this stage, improving efficiency and reducing energy consumption. - Mineral Separation:

Mineral separation aims to separate valuable minerals from the ore matrix. Techniques like gravity separation, magnetic separation, and froth flotation are commonly employed. These methods exploit the differences in physical and chemical properties of minerals, enabling their selective separation. Innovations in separation technologies, such as sensor-based sorting, have enhanced efficiency and reduced the need for chemical reagents. - Concentration and Refining:

Once minerals are separated, further processing is often required to obtain a marketable product. Concentration techniques, such as smelting, leaching, and electrowinning, are utilized to increase the mineral content. Refining processes, including pyrometallurgy and hydrometallurgy, remove impurities and enhance the purity and quality of the final product. - Environmental Considerations:

Mineral mining and processing can have significant environmental impacts. To mitigate these effects, industry stakeholders employ various strategies. These include implementing sustainable mining practices, minimizing water and energy consumption, adopting efficient waste management systems, and rehabilitating mined areas. Additionally, advancements in eco-friendly technologies, such as bioleaching and phytomining, are being explored.

Conclusion:

The mining and processing of minerals are complex and multifaceted processes that require expertise, precision, and responsible practices. From exploration and extraction to separation and refining, each stage presents unique challenges and opportunities for innovation. By understanding and implementing efficient techniques, the mineral industry can ensure sustainable resource utilization while minimizing environmental impact. As technology continues to advance, the future of mineral mining and processing holds promising prospects for increased efficiency, reduced environmental footprint, and enhanced resource management.