Capacitors are essential components in electronic circuits, storing and releasing electrical energy. Over time, capacitors can degrade or fail, leading to circuit malfunctions. In this blog post, we will explore advanced techniques to test the functionality of capacitors, ensuring their proper operation in various applications.

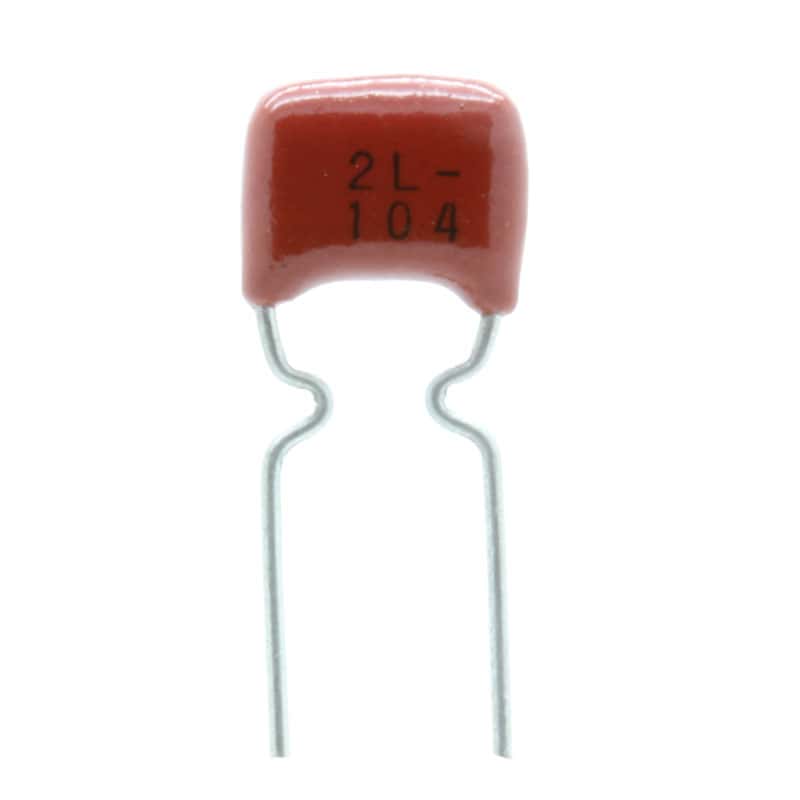

- Visual Inspection:

Before conducting any tests, visually inspect the capacitor for physical damage, such as bulging, leaking, or discoloration. These signs indicate potential issues and may require immediate replacement. - Capacitance Measurement:

Capacitance is a fundamental property of capacitors, representing their ability to store charge. To measure capacitance accurately, use a digital multimeter (DMM) with a capacitance measurement function. Follow these steps:

a. Discharge the capacitor by shorting its terminals with a resistor.

b. Connect the DMM leads to the capacitor terminals, ensuring correct polarity.

c. Read the capacitance value displayed on the DMM. Compare it with the capacitor's rated capacitance. A significant deviation suggests a faulty capacitor. - ESR (Equivalent Series Resistance) Measurement:

ESR is the internal resistance of a capacitor, affecting its ability to filter and store charge efficiently. High ESR can lead to circuit instability. To measure ESR, follow these steps:

a. Disconnect the capacitor from the circuit.

b. Use an ESR meter or a specialized capacitor analyzer capable of ESR measurement.

c. Connect the meter's probes to the capacitor terminals, observing polarity.

d. Read the ESR value displayed on the meter. Compare it with the manufacturer's specifications. Elevated ESR indicates a potential capacitor failure. - Leakage Current Test:

Leakage current refers to the small amount of current that flows through a capacitor when it should be inactive. Excessive leakage current can cause circuit malfunction. To perform a leakage current test:

a. Disconnect the capacitor from the circuit.

b. Use a digital multimeter capable of measuring current in the microampere range.

c. Connect the multimeter in series with the capacitor, ensuring correct polarity.

d. Apply the rated voltage to the capacitor and measure the leakage current. Compare it with the manufacturer's specifications. Higher leakage current suggests a faulty capacitor. - Temperature and Voltage Stress Testing:

Capacitors may exhibit different behaviors under varying temperature and voltage conditions. Stress testing helps identify potential issues that may arise in real-world applications. Follow these steps:

a. Use a temperature chamber to subject the capacitor to extreme temperatures within its specified range.

b. Apply voltages higher than the rated voltage to the capacitor and monitor its behavior.

c. Observe any changes in capacitance, ESR, or leakage current during and after the stress test. Significant deviations from expected values indicate potential problems.

Conclusion:

Testing the functionality of capacitors is crucial to ensure the reliability and performance of electronic circuits. By employing advanced techniques such as capacitance measurement, ESR measurement, leakage current testing, and stress testing, you can accurately assess the condition of capacitors and take appropriate actions, such as replacement or further troubleshooting. Regular testing and maintenance will help prevent unexpected failures and optimize the overall performance of electronic systems.