Mechanical seals and magnetic drives are two common types of sealing technologies used in pumps and other rotating equipment. Both technologies have their advantages and disadvantages, and the choice between them depends on various factors such as the application, the fluid being pumped, and the operating conditions. In this article, we will compare mechanical seals and magnetic drives and help you determine which is the better choice for your specific needs.

Section 1: Mechanical Seals

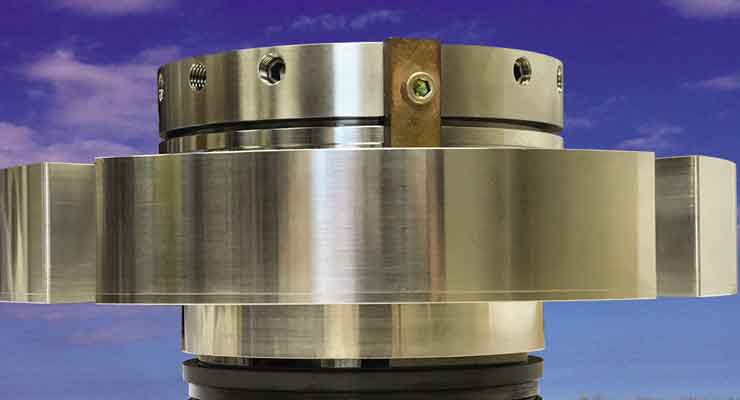

Mechanical seals are a type of sealing technology that uses a stationary and a rotating face to create a seal. The stationary face is typically made of a hard material such as ceramic, while the rotating face is made of a softer material such as carbon. The two faces are pressed together with a spring or other mechanism to create a seal that prevents fluid from leaking out of the pump.

Advantages of Mechanical Seals:

- Can handle a wide range of fluids and temperatures

- Can handle high pressures and speeds

- Easy to install and maintain

- Can be repaired or replaced without replacing the entire pump

Disadvantages of Mechanical Seals:

- Can wear out quickly if not properly lubricated

- Can be prone to leakage if not installed or maintained correctly

- Can be more expensive than other sealing technologies

Section 2: Magnetic Drives

Magnetic drives are a type of sealing technology that uses a magnetic coupling to transfer torque from the motor to the impeller. The magnetic coupling consists of two magnets, one on the motor side and one on the impeller side, that are separated by a non-magnetic barrier. When the motor rotates, the magnetic field causes the impeller to rotate as well, without any physical contact between the two.

Advantages of Magnetic Drives:

- No physical contact between the motor and the fluid being pumped, which eliminates the risk of leakage

- Can handle corrosive and hazardous fluids

- Can operate at high temperatures and pressures

- Low maintenance and long service life

Disadvantages of Magnetic Drives:

- Limited to low to medium speeds and pressures

- Can be more expensive than other sealing technologies

- Can be less efficient than other sealing technologies

Section 3: Which is the Better Choice?

The choice between mechanical seals and magnetic drives depends on various factors such as the application, the fluid being pumped, and the operating conditions. In general, mechanical seals are a better choice for high-speed and high-pressure applications, while magnetic drives are a better choice for corrosive and hazardous fluids. However, there are exceptions to these general rules, and it is important to consult with a pump expert to determine the best sealing technology for your specific needs.

Conclusion:

Mechanical seals and magnetic drives are two common types of sealing technologies used in pumps and other rotating equipment. Both technologies have their advantages and disadvantages, and the choice between them depends on various factors such as the application, the fluid being pumped, and the operating conditions. By understanding the pros and cons of each technology, you can make an informed decision and choose the best sealing technology for your specific needs.