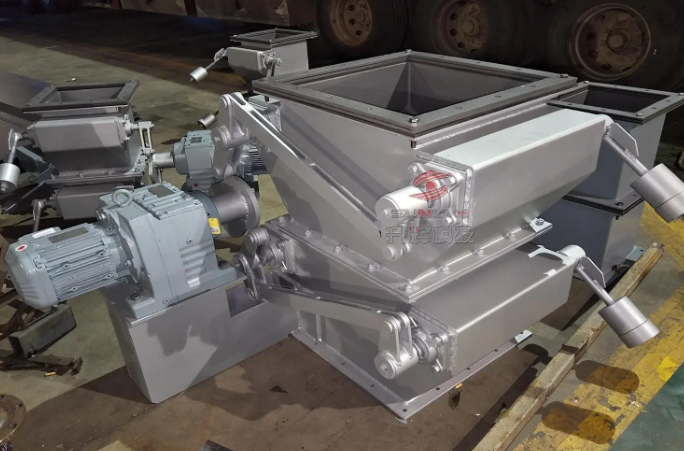

Efficient and reliable material handling is crucial for industries like cement production and metallurgy, where bulk materials are transported at high temperatures. The Sunlike High Temperature Electric Double Flap Valve has emerged as a key component in optimizing industrial material handling systems, ensuring safe, stable, and high-throughput operations.

With over 200 employees and extensive R&D capabilities, Sunlike Machinery has designed and manufactured valves that meet rigorous industry demands, offering superior performance in harsh working environments.

High Temperature Resilience for Cement and Metallurgy Processes

Cement kilns, metallurgical furnaces, and related processing equipment often operate at extremely high temperatures. Standard valves may fail under such conditions, leading to material loss, safety hazards, and operational downtime. The Sunlike High Temperature Electric Double Flap Valve addresses these challenges by:

-

Maintaining structural integrity under temperatures exceeding 500°C.

-

Preventing material leakage, reducing dust pollution, and ensuring a safer working environment.

-

Enabling continuous operation without the risk of deformation or failure.

This high-temperature resilience directly contributes to more efficient and optimized material handling in demanding industrial contexts.

Precision Control and Automation

The valve’s electric double flap design allows precise control over material flow. Key features include:

-

Dual flap operation: Enables fine regulation of bulk material discharge, reducing spillage and optimizing flow rates.

-

Automated control system: Interfaces seamlessly with central industrial control systems, allowing real-time monitoring and adjustments.

-

Energy efficiency: Reduces energy consumption by minimizing unnecessary air loss and material blockage.

By integrating automation, plants can achieve higher throughput and reduced operational costs, enhancing overall industrial material handling efficiency.

Durability and Maintenance Advantages

Industrial operations demand equipment that combines durability with low maintenance. The Sunlike valve excels in this regard:

-

Robust construction: Manufactured from high-grade steel and heat-resistant components.

-

Minimal wear: Double flap design distributes stress evenly, extending service life.

-

Ease of maintenance: Modular components simplify inspection, cleaning, and replacement without prolonged shutdowns.

These factors reduce downtime and extend operational lifespan, supporting continuous production in cement and metallurgy facilities.

Adaptability to Diverse Industrial Applications

The Sunlike High Temperature Electric Double Flap Valve is suitable for a wide range of industrial material handling applications, including:

-

Cement industry: Handling clinker, raw meal, fly ash, and cement powders.

-

Metallurgy: Regulating the flow of iron ore, slag, and other high-temperature granular materials.

-

Bulk material transport: Integration into pneumatic conveyors, storage silos, and feed systems.

This versatility ensures that plants can standardize their material handling processes across multiple sections, improving efficiency and reducing operational complexity.

Optimizing Workflow and Reducing Operational Risk

Installing high-temperature electric double flap valves offers strategic advantages beyond flow regulation:

-

Enhanced safety: Prevents dust explosions, material blockages, and accidental overflows.

-

Consistent material delivery: Enables steady feeding of materials into production lines, avoiding disruptions.

-

Reduced labor dependency: Automated control minimizes manual intervention, allowing operators to focus on critical tasks.

These benefits directly support the optimization of industrial material handling, enhancing production efficiency and safety.

FAQ

Q1: What industries benefit most from Sunlike High Temperature Electric Double Flap Valves?

A1: Primarily cement production, metallurgy, bulk material handling, and other high-temperature industrial processes.

Q2: How does the valve improve material handling efficiency?

A2: By providing precise flow control, reducing spillage, and enabling automated integration with central control systems.

Q3: Can it withstand continuous operation at extreme temperatures?

A3: Yes, the valve is engineered to operate reliably under temperatures exceeding 500°C without deformation or failure.

Q4: What maintenance is required for optimal performance?

A4: Minimal maintenance is needed due to its robust design and modular components, which simplify inspections and replacements.

Q5: How does it enhance safety in industrial plants?

A5: By preventing material leakage, reducing dust accumulation, and maintaining controlled flow to avoid blockages and potential hazards.

Conclusion

For industrial operations in cement and metallurgy, efficient and reliable material handling is a critical factor for productivity and safety. The Sunlike High Temperature Electric Double Flap Valve delivers unmatched performance in extreme conditions, precise material flow control, and low maintenance requirements. By integrating this valve into material handling systems, plants can achieve optimized workflows, enhanced safety, and improved operational efficiency.

Sunlike Machinery continues to innovate in industrial valve technology, supporting high-temperature applications and enabling cement and metallurgy plants to reach new levels of performance and reliability.

www.cn-sunlike.com

Nantong Sunlike Machinery Co., Ltd.