In industrial operations, the reliability and efficiency of ball mills are vital for processing materials effectively. One critical component that often goes overlooked is the bearing bush. Selecting the right ball mill bearing bush can significantly impact the mill's performance, longevity, and maintenance costs.

Sawei Equipment Technology, a leader specializing in turnkey process equipment solutions for industries such as agrochemicals and bio-fermentation, emphasizes the importance of choosing the correct bearing bush to optimize ball mill operations.

Here are the top five factors you should consider when choosing a ball mill bearing bush.

1. Material Compatibility

The bearing bush material must be compatible with the operating environment and the materials processed in the ball mill. For example, in fertilizer production or chemical processing, exposure to corrosive substances requires bearing bushes made from corrosion-resistant materials to prevent premature wear and failure.

2. Load Capacity and Strength

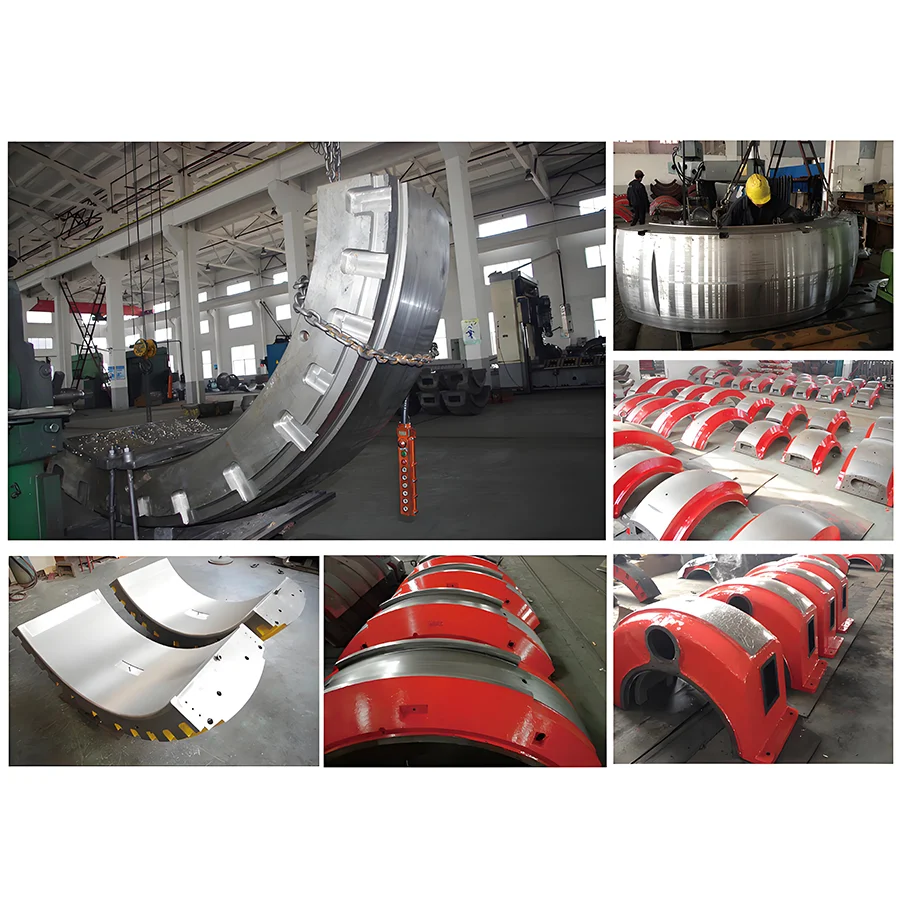

Bearing bushes must withstand the heavy loads and high stresses typical in ball mill operations. Assess the maximum load the bush can support without deformation. Sawei Equipment Technology designs bearing bushes with materials and structures tailored to handle industrial-scale loads in sectors like phosphate and sulfur chemical processing.

3. Wear Resistance and Durability

Since ball mills involve continuous rotation and friction, the bearing bush should exhibit excellent wear resistance. Choosing bushes made from high-quality alloys or composites can extend service life and reduce downtime, especially in harsh industrial environments such as bio-fermentation waste gas recovery.

4. Lubrication Requirements

Proper lubrication is essential for bearing bush performance. Consider bushes that are compatible with available lubrication methods, whether oil, grease, or self-lubricating materials. Efficient lubrication reduces friction, heat, and wear, enhancing operational stability.

5. Ease of Maintenance and Replacement

Industrial processes demand minimal downtime. Bearing bushes that are easy to install, inspect, and replace help maintain smooth operations. Sawei Equipment Technology prioritizes designing equipment with user-friendly maintenance in mind, supporting rapid servicing in chemical and environmental applications.

Why Choose Sawei Equipment Technology’s Solutions?

Sawei Equipment Technology offers comprehensive expertise in developing process equipment for complex industries. Their bearing bushes and associated components are engineered for robustness, reliability, and tailored performance. By integrating industry-specific knowledge with advanced manufacturing, Sawei ensures clients receive components that maximize efficiency and minimize operational risks.

Conclusion

Selecting the right ball mill bearing bush is a crucial decision that affects the performance and longevity of your milling equipment. By considering material compatibility, load capacity, wear resistance, lubrication, and maintenance ease, you can optimize your ball mill’s operation.

Partnering with a reputable provider like Sawei Equipment Technology ensures you get high-quality, tailored solutions designed to meet the demanding needs of industries such as fertilizers, chemicals, and bio-fermentation.

www.swasps.com

Jiangsu Sawei Equipment Technology Co., Ltd.