In the polymer processing industry, foaming agents play a pivotal role in enhancing the quality and performance of various plastic products. Among these, composite foaming agents have emerged as a superior choice, offering multiple benefits that improve production efficiency and product characteristics.

Youlihong New Material Co., Ltd., a leading enterprise specializing in PVC processing additives, calcium-zinc stabilizers, and a wide range of polymer auxiliaries, has been at the forefront of developing innovative composite foaming agents tailored to meet diverse industrial needs.

Here are the top five advantages of using composite foaming agents in polymer processing:

1. Improved Foam Quality and Uniformity

Composite foaming agents enable the production of polymers with a finer and more uniform cell structure. This improved foam quality enhances the mechanical properties of the finished product, such as strength, flexibility, and impact resistance. With Youlihong’s advanced formulations, manufacturers can achieve consistent foaming performance across various polymer types.

2. Enhanced Process Stability

In polymer processing, maintaining stable production conditions is crucial. Composite foaming agents help regulate the foaming reaction, reducing defects like uneven cell sizes or collapse. This stability minimizes material waste and lowers production costs, making the process more efficient and reliable.

3. Versatility Across Different Polymers

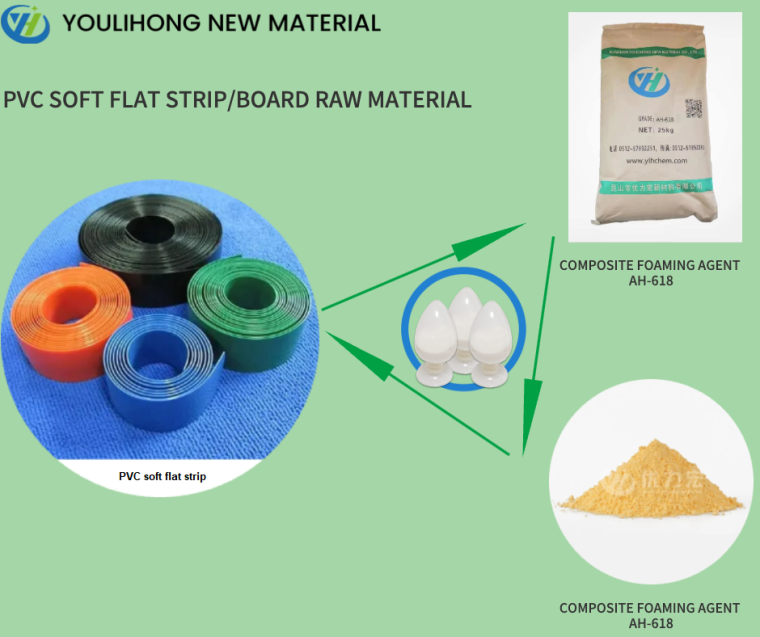

Composite foaming agents are compatible with a broad range of polymers, including PVC, WPC (wood-plastic composites), and other plastic materials. This versatility allows manufacturers to use a single foaming agent formulation for multiple products, simplifying inventory and supply chain management. Youlihong’s product lineup supports diverse polymer processing needs, from rigid PVC profiles to flexible foamed sheets.

4. Improved Surface Finish and Appearance

Using composite foaming agents can result in smoother surface finishes on foamed products. This aesthetic improvement is particularly important for consumer-facing applications where visual appeal matters. The controlled foaming action reduces surface imperfections, enabling manufacturers to deliver higher-quality products with less post-processing.

5. Environmental and Cost Benefits

Composite foaming agents often reduce the amount of raw material required by creating lightweight foamed structures without compromising strength. This leads to material savings and lower transportation costs. Additionally, advanced composite foaming agents from companies like Youlihong are designed to comply with environmental regulations, supporting sustainable production practices.

Conclusion

Composite foaming agents are transforming polymer processing by providing manufacturers with superior control, quality, and cost-effectiveness. With expertise from Youlihong New Material Co., Ltd., companies can access innovative foaming solutions that optimize their production and meet evolving market demands.

Whether you are working with PVC, WPC, or other polymer materials, integrating composite foaming agents into your process can elevate your product’s performance and appeal.

Contact Youlihong New Material Co., Ltd. today to learn more about their comprehensive range of polymer processing additives and foaming agents.

www.ylhchem.com

Youlihong New Material(KunShan) Co.,Ltd.